Keeping in hands a still warm GE Annual Report, a company-wide document that targets out stakeholders & customers around the world, it’s a pleasure to see and hear about successes of own design.

Keeping in hands a still warm GE Annual Report, a company-wide document that targets out stakeholders & customers around the world, it’s a pleasure to see and hear about successes of own design.

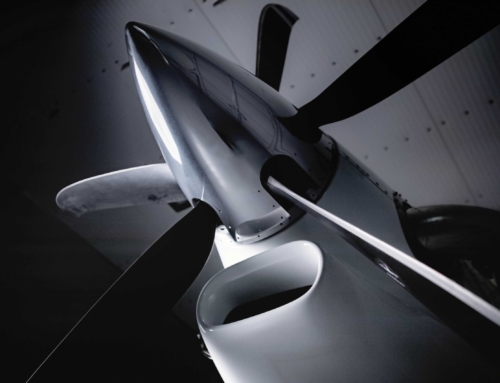

EDC Project was the major HGP redesign owned by EDC PGP Turbine Module Team and our latest big achievement in Turbine Module. It is highly appreciated by our well known customer DubAl. Our solution was featured in 2013 report as one of a few projects highlighting “Leading in productivity” chapter.

EDC team led the redesign of all HGP components: buckets, nozzles and shrouds, what effected in 9E turbine performance increase. As an extension to design responsibilities the team instrumented and validated on field new design performing first 9E turbine tests and one of very few in entire E-class turbines.

“Dubai Aluminium (DUBAL) was the first GE customer to adopt our Advanced Gas Path (AGP) technology for its installed 9E gas turbines, powering one of the world’s largest aluminium smelters. AGP, part of our Power LifeMax™ portfolio of hardware and software blended solutions, was engineered based on our analysis of over 100 million hours of gas turbine operating data. It can deliver industry-leading upgrade performance, reduce fuel consumption and extend the life of turbine assets. The result for DUBAL was 3.4% higher output and a 1.5% increase in fuel efficiency, which helped expand production and reduce costs.”