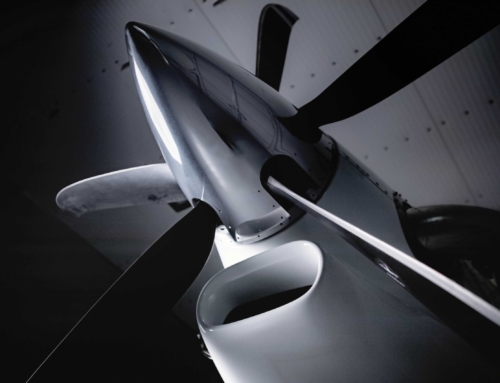

Polish engineers from General Electric Company Polska Sp. z o.o. in cooperation with the Łukasiewicz Research Network – Institute of Aviation are now on the home stretch to certify a breakthrough aircraft engine, which means that the project Development of the advanced turboprop engine power turbine containing 3D printed hardware, co-financed by the European Union under the Smart Growth Operational Programme 2014-2020, is coming to an end. As part of the project, a talented and highly skilled group of engineers developed and led the production of a groundbreaking low-pressure turbine for a turboprop engine that will soon propel the most modern aircraft.

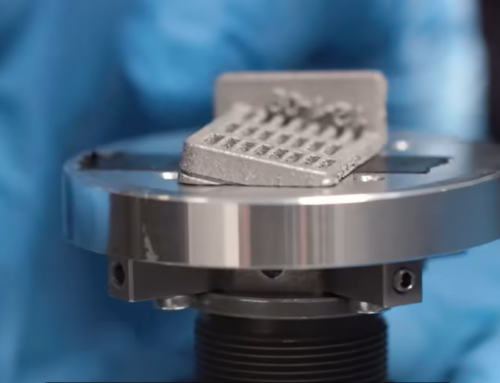

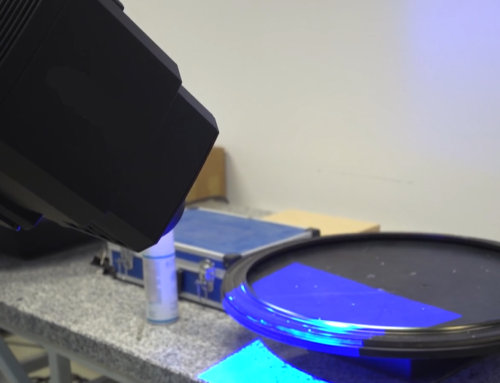

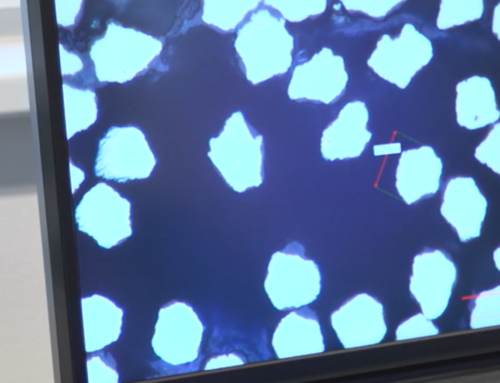

The t![]() urbine contains components produced in additive methods, which is a quantum leap in the field of aircraft engine construction. The term “incremental methods” (also known as 3D printing) is self-explanatory as the process simply involves building parts by adding material layer by layer. The layers are later combined using a laser or other energy source. Conventional methods of production mean removal, e.g., by milling the material from a blank in the form of a cast or forging. The main advantages of the new method are material saving and the possibility of obtaining shapes unattainable by traditional methods, and thus eliminating connections and elements from the construction, which until now had to be made only due to production restrictions. Additive technology was used to create key elements of the new turbine, which allowed to reduce the weight and number of elements that make up the entire turbine module. This in turn made it possible to cut down fuel consumption and increase the reliability of the entire engine. Something that once seemed to be reserved for science fiction authors, is now becoming a reality.

urbine contains components produced in additive methods, which is a quantum leap in the field of aircraft engine construction. The term “incremental methods” (also known as 3D printing) is self-explanatory as the process simply involves building parts by adding material layer by layer. The layers are later combined using a laser or other energy source. Conventional methods of production mean removal, e.g., by milling the material from a blank in the form of a cast or forging. The main advantages of the new method are material saving and the possibility of obtaining shapes unattainable by traditional methods, and thus eliminating connections and elements from the construction, which until now had to be made only due to production restrictions. Additive technology was used to create key elements of the new turbine, which allowed to reduce the weight and number of elements that make up the entire turbine module. This in turn made it possible to cut down fuel consumption and increase the reliability of the entire engine. Something that once seemed to be reserved for science fiction authors, is now becoming a reality.

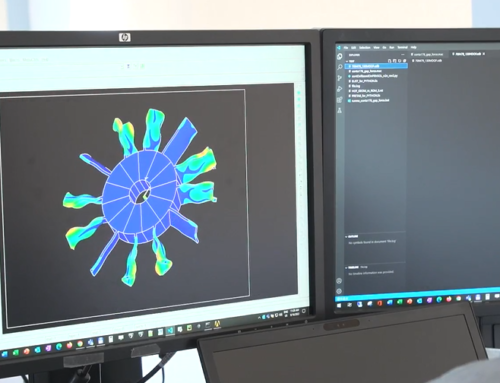

Over the course of the project, several test engines were designed and built, which enabled us to check the engine’s behavior under different conditions and with diff erent loads. We used the data collected during those tests to implement improvements and updates to the turbine design. During the test campaign, it was possible to confirm all the assumptions made at the beginning of the project, the engine underwent trials, among others in Canada and the Czech Republic, to finally take the first independent flight in Berlin. General Electric Company Polska Sp. z o.o. has gained significant know-how in the field of design and production of an innovative turbine and specifically with the use of additive methods. The acquired knowledge and skills place engineers from Warsaw at the forefront of world aviation engineering and are a clear proof they are able to use innovative solutions and technologies.

erent loads. We used the data collected during those tests to implement improvements and updates to the turbine design. During the test campaign, it was possible to confirm all the assumptions made at the beginning of the project, the engine underwent trials, among others in Canada and the Czech Republic, to finally take the first independent flight in Berlin. General Electric Company Polska Sp. z o.o. has gained significant know-how in the field of design and production of an innovative turbine and specifically with the use of additive methods. The acquired knowledge and skills place engineers from Warsaw at the forefront of world aviation engineering and are a clear proof they are able to use innovative solutions and technologies.

Three test engines are currently being assembled to confirm the latest certification requirements. The engine is expected to be certified in 2024.

Project part-financed by the European Union within the European Regional Development Fund