The GE90 engine experienced its most successful year in 2011, accumulating airline and freighter operator commitments for 400 engines with a list price of more than $11 billion. This surpasses the previous record of 250 engine commitments in 2007.

This year included a record-setting Emirates’ order for 50 Boeing 777s, powered by GE90-115B engines, announced at the Dubai Air Show in November.

“The Boeing 777 and GE90 engine combination is growing in popularity with customers worldwide and is the best-selling aircraft-engine combination in its class,” said Bill Millhaem, general manager of the GE90 Program at GE Aviation. “Total orders for the GE90 engine family now exceed 2,000 engines with a backlog of 800 engines that will be delivered in the next four years.”

The 200 aircraft commitments announced in 2001 are for GE90-powered Boeing 777-300ERs and Freighters.

The production rate for the GE90 is growing, with plans to produce more than 180 GE90 engines in 2012 up from 170 engines in 2011. The production rate is expected to climb to 225 engines in 2014.

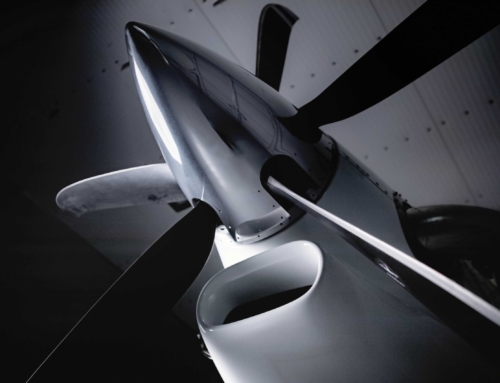

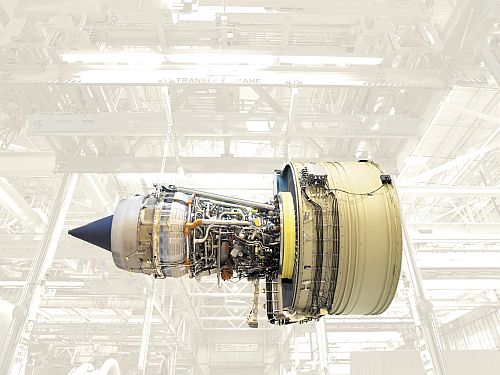

The GE90 story centers on an extraordinary faith in technology. In 1990, the late Brian Rowe, the architect behind GE Aviation’s rise to the top of the jet propulsion industry and former President and CEO, announced the new baseline GE90 concept. Launched on the 777, the GE90 featured several technology “firsts”—including carbon-fiber composite fan blades.

As the Boeing 777 aircraft grew in size thus requiring higher thrust engines, customer demand for the GE90 soared. The GE90-115B engine, developed for the 777-300ER and 777-200LR, entered service in 2002—the best service entry for any large GE engine at that time. The engine has continued its stellar performance with an in-flight shutdown rate (IFSD) of 0.001, which means only one engine IFSD per one million engine flight-hours.

Since then, the GE90 has influenced every commercial engine developed at GE Aviation. The GE90 formed the basis for the best-selling GEnx for the new Boeing 787, and provided the core hot section for the Engine Alliance* GP7200 engine for the A380. The GE90 architecture also influenced the new CFM International+ LEAP engine, the best-selling engine for the Boeing 737 MAX, Airbus A320neo, and COMAC C919 aircraft.

In addition to an unrivaled thrust rating of 115,000 pounds, the GE90-115B offers the enhanced performance and efficiency of three-dimensional, aerodynamic (3D aero) compressor airfoils and wide-chord, swept composite fan blades. The GE90-115B performance and efficiency, coupled with the GE90-115B dual annular combustor technology, significantly limits fuel consumption and restricts hydrocarbon emissions to 40 percent of the level permitted by current international standards.

Snecma of France, Avio SpA of Italy and IHI Corporation of Japan are revenue-sharing participants in the GE90 program.

The GE90-115B engine is part of GE’s “ecomagination” product portfolio—GE’s commitment to implementing innovative, cost-effective technologies that enhance the customers’ environmental and operating performance.

The manufacturing of the GE90 engine involves the following GE locations in the United States:

- Asheville, North Carolina: seals, splitter, retainers, spinner support

- Batesville, Mississippi: composites (fan stator case, acoustic panels, fan platforms)

- Dayton, Ohio: tubes, ducts, manifolds

- CFAN San Marcos, Texas: composite fan blades

- Durham, North Carolina: engine assembly and overhaul

- Evendale, Ohio: design and development testing

- Greenville, South Carolina: turbine blades

- Hooksett, New Hampshire: stator vanes (stationary airfoils) and tubes

- Lynn, Massachusetts: CD plate, combustor liner, combustor case

- Madisonville, Kentucky: turbine airfoils

- Peebles, Ohio: final assembly and engine testing

- Rutland, Vermont: airfoils (fan booster and compressor)

- Terre Haute, Indiana: No. 1 bearing housing, combustor liners, centershields for combustor assembly

- Victorville, California: flight testing

- West Jefferson, North Carolina: high-pressure turbine disks and shafts, compressor disks, and fan disks

- Wilmington, North Carolina: stage 1 high-pressure turbine disk, spool, fan disk, mid seal

GE Aviation, an operating unit of GE (NYSE: GE), is a world-leading provider of jet and turboprop engines, components and integrated systems for commercial, military, business and general aviation aircraft. GE Aviation has a global service network to support these offerings. For more information, visit us at www.ge.com/aviation. Learn more about GE Business & General Aviation at http://facebook.com/GEBGA. Follow GE Aviation on Twitter at http://twitter.com/GEAviation and YouTube at http://www.youtube.com/user/GEAviation.