Project start date: 01.01.2020 / Project completion date: 30.10.2023

“DEVELOPMENT OF A NEW HEAT RESISTANT COMPOSITE MATERIAL FOR USE IN AIRCRAFT ENGINE COMPONENTS”

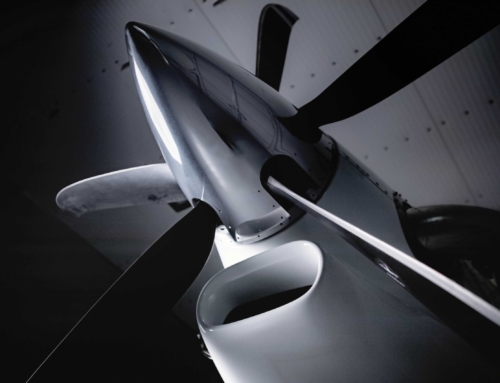

On January 1, 2020, a group of GE Aerospace engineers took up a new challenge: to develop an innovative product in a form of a composite material based on inorganic polymer resins; and to progress its manufacturing technology. The expectation behind the new material has been its increased high temperature capability, to potentially replace currently used metallic alloys and expand the range of composite materials use. In addition to being able to operate in high-temperature environments the new composite is expected to be lightweight and hence to enable weight reduction opportunities in new design areas. This would result in lower fuel consumption and reduced greenhouse gas emissions from engine operations.

The project was implemented under the Smart Growth Operational Programme 2014-2020 and is co-financed by the European Union under the European Regional Development Fund. Today, it is already at its final stage and its results have allowed to achieve the assumed goals of the project. As part of the research and development works, GE Aerospace Poland engineers, with the participation of a Łukasiewicz Research Network – Institute of Aviation in Warsaw and support of global teams from GE Research and GE Aerospace Evendale, carried out a wide range of research and design works aimed at executing three stages of the project.

These also constituted the main milestones in the technology development:

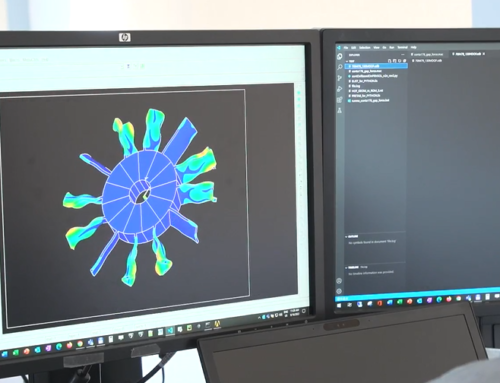

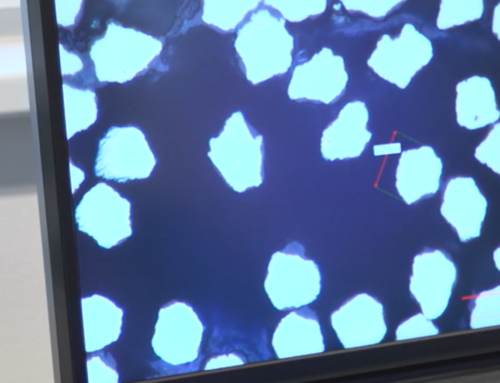

Stage 1 – validation of the basic assumptions of the project – compatibility of the components of the composite material,

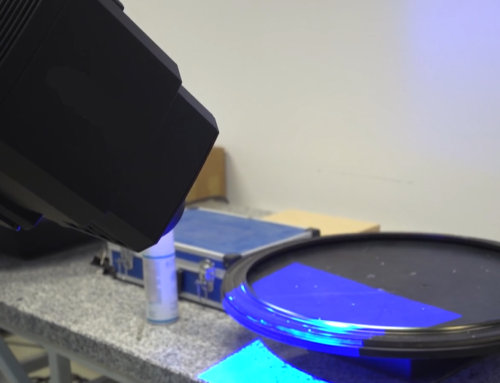

Stage 2 – development of optimum production parameters of the new types of composite materials in order to validate end product concept in laboratory conditions,

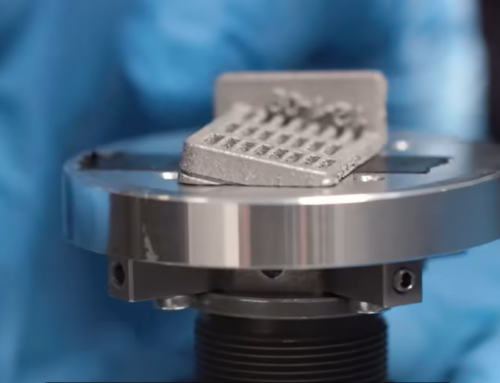

Stage 3 – demonstration of the technology through production of engine representative component geometry to validate feasibility of manufacturing of part with higher degree complexity.

The three years of intense work resulted in success and fulfilment of the project’s objectives. The obtained material has a great potential to become an important building block of next-generation aircraft engine components, offering further opportunities for weight reduction of an aircraft engine structures.

Project co-financed by the European Union under the European Regional Development Fund