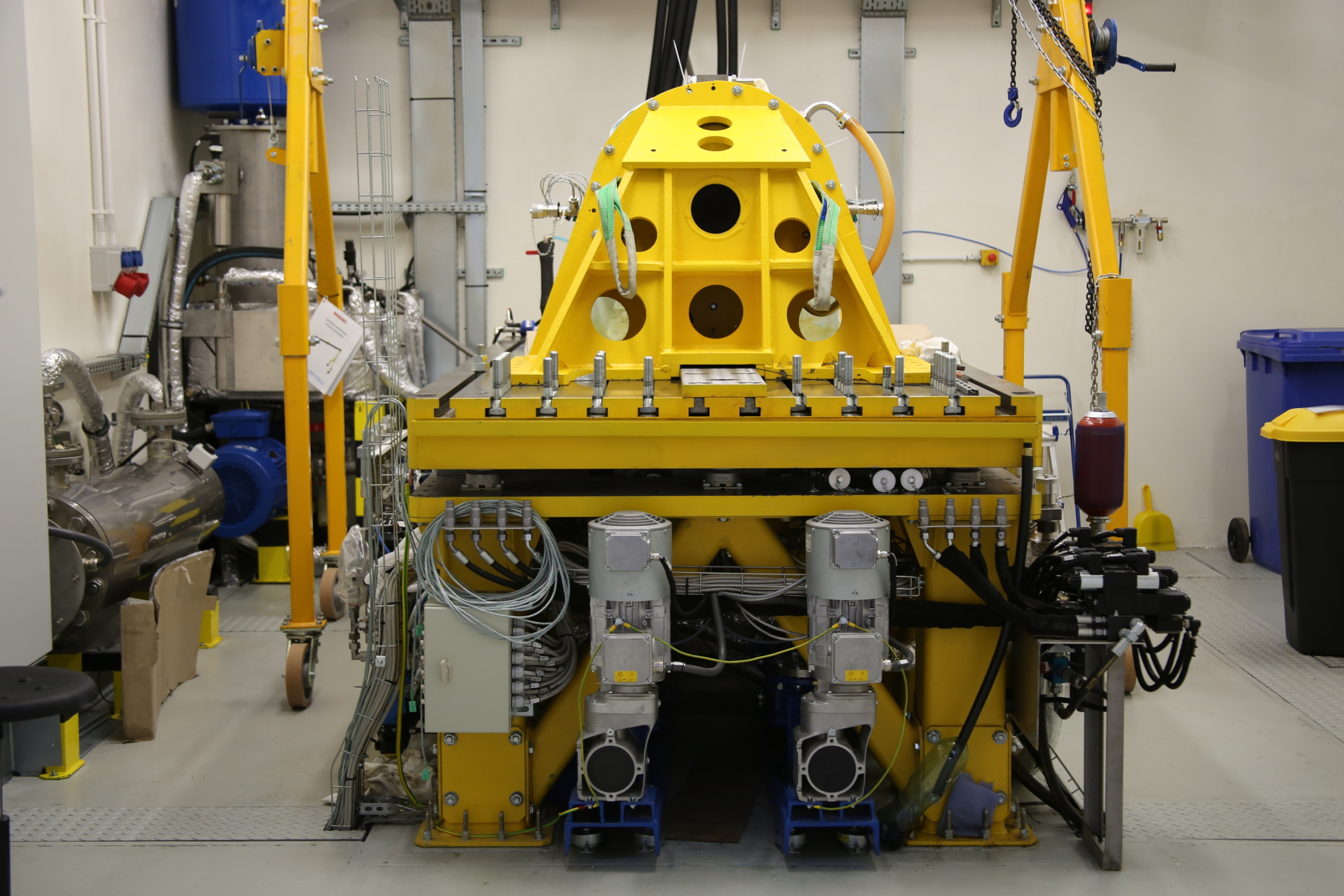

Component Test Laboratory

Who we are

In our laboratory we have three test stands for durability and functional tests of aircraft engine components (rolling and slide bearings, shaft seals, oil carriers, gear boxes, heat exchangers, etc.) and other objects for which the test parameters are within the scope of the available test stands.

Labs technical capabilities include:

- rotational speed up to 52,000 rpm, drive power 150 kW,

- pneumatic installation with a capacity up to 2.2 kg/s of compressed air, pressure of up to 8 bar and temperature of up to 500 °C,

- lubrication system with an output of up to 120 l/min, pressure of 40 bar and temperature of up to 150 ° C,

- hydraulic system for input of pressure up to 210 bar and up to 100 kN.

What we do

Using the laboratory infrastructure, we can simulate aviation engine operating conditions, such as hot oil supply, applying forces and pressurizing with cold or hot air. With the advanced control and data acquisition system we can perform tests in either manual or automatic mode, while recording the operating parameters such as temperature, pressure, flows, vibrations, deformations and speeds at frequencies up to 25 kHz.

Lab competences:

Any other testing needs?

Contact us!

605 602 543