Additive Manufacturing Technology Laboratory

Who we are

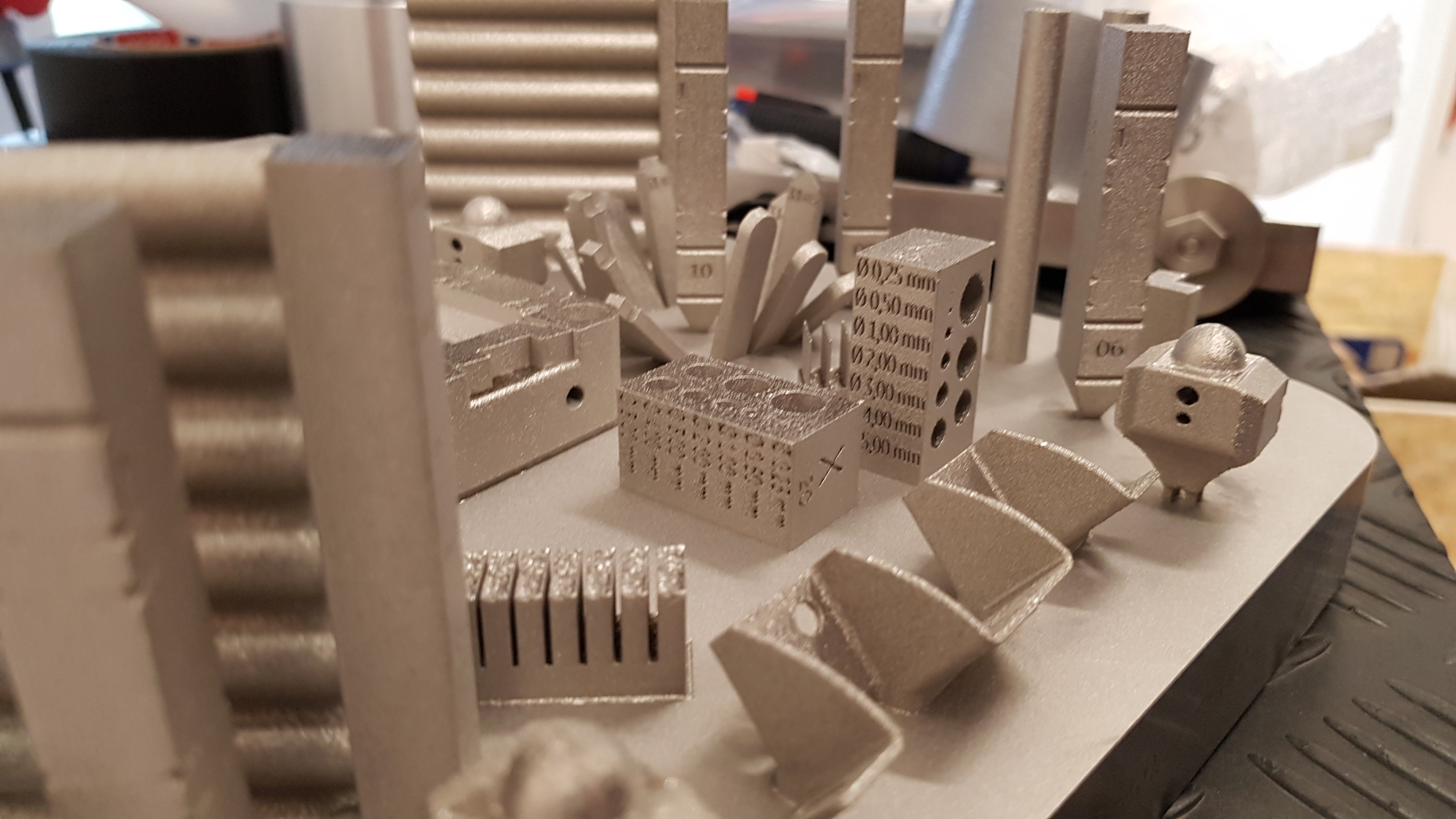

Additive Laboratory specializes mainly in additive DMLM technology (Direct Metal Laser Melting).

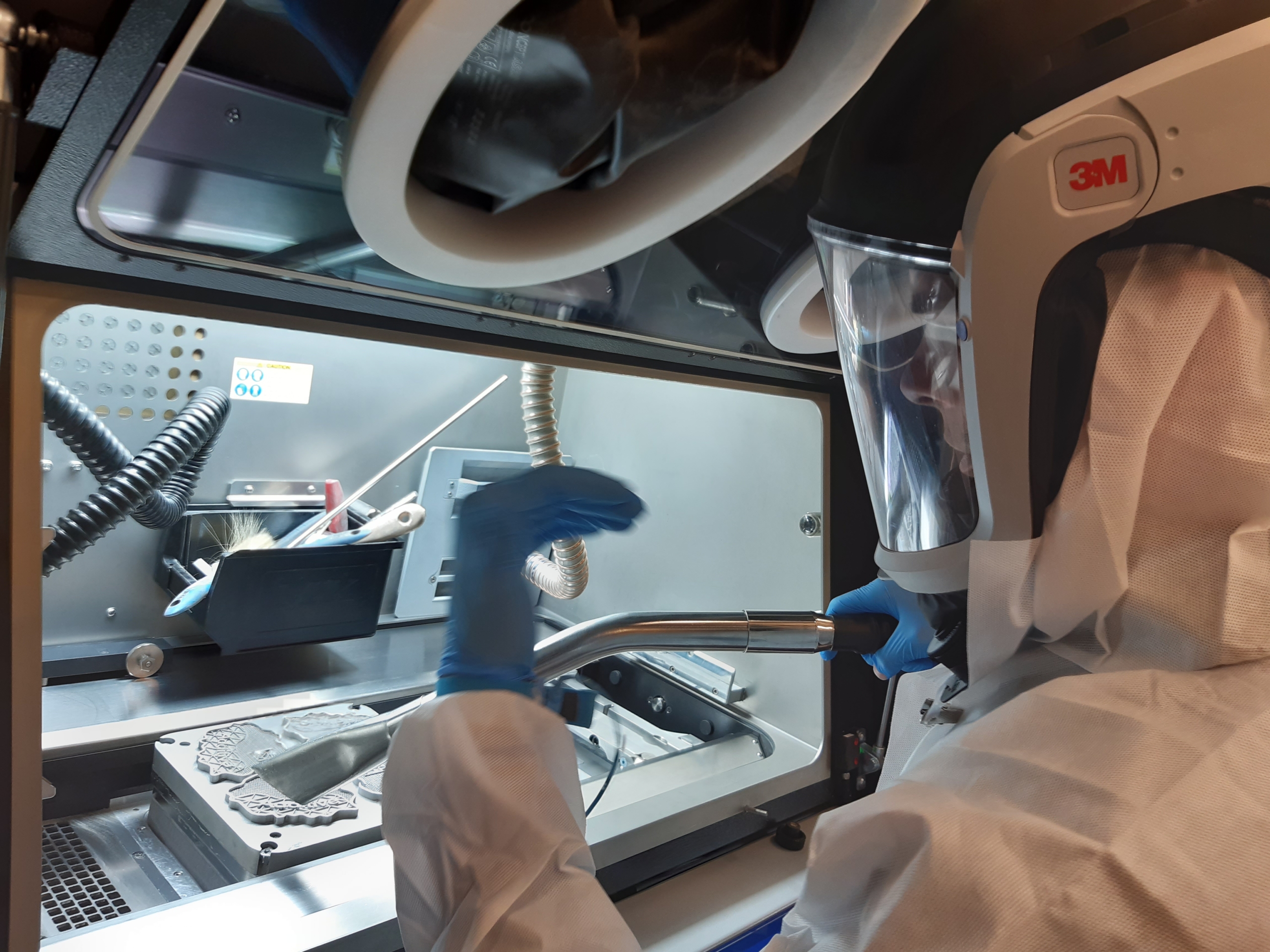

DMLM is an additive manufacturing process that uses lasers to melt ultra-thin layers of metal powder to build a three-dimensional object. The use of a laser to selectively melt thin layers of tiny particles yields objects exhibiting fine, dense and homogeneous characteristics. The most popular materials used in this technology are: titanium alloy, stainless steel, tool steels, In718 or CoCr as a superalloy, aluminum alloys and surgical steels.

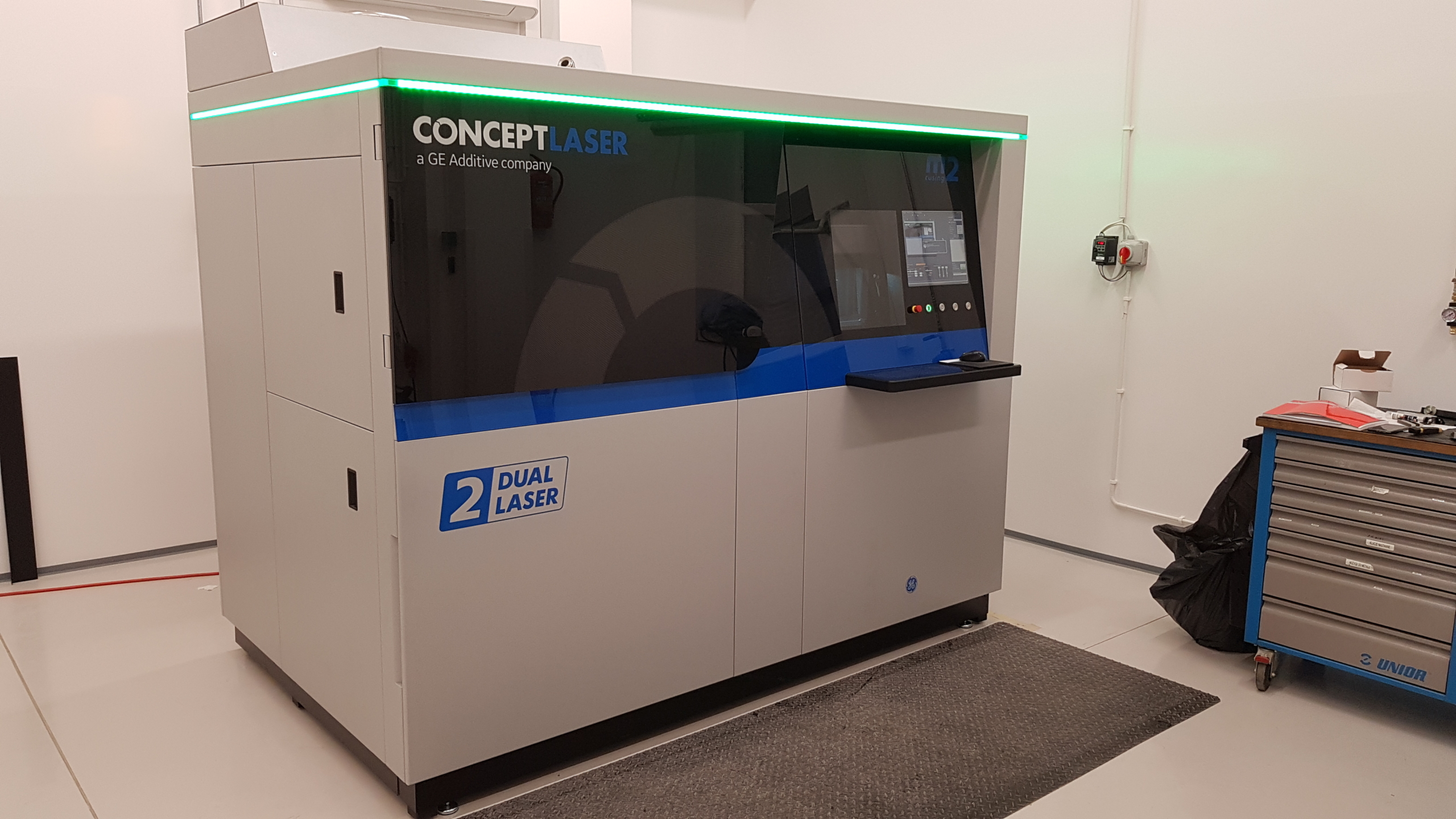

The laboratory has the newest DMLM M2 Cusing Multilaser machine produced by Concept Laser from the GE Additive group. This is the second generation of the well-known M2 Classic version with increased build volume to 250 x 250 x 350 mm3 and laser power up to 2×400 W. The machine has several control and monitoring systems enabling continuous supervision to ensure the best quality of the product, repeatability and safety of the printing process. High-class equipment allows engineers to conduct research projects related to additive technology and to obtain real prototypes of aircraft engine parts, on the development of which and introduction to the real world, they are constantly working.

What we do

Our lab delivers advanced 3D solutions for business. We provide services of rapid prototyping and rapid production of tools using additive methods.

Additive laboratory can deliver 3D printing services of parts in FDM (polymer) and DMLM (metal) technology. On top of that, we are equipped with advanced technology that allows us to simulate printing process via Powder Bed Fusion.

We specialize in the development and optimization of the part of manufacturing process using 3D DMLM (metal) printing technology, mainly for the aviation and aerospace businesses. Our capabilities include:

- Modeling of deformations

- Analysis and optimization of part geometry to adjust it for the 3D manufacturing

- Selection and optimization of printing parameters

- Adjusting the parameters for processing parts after printing

- Optimization of inspection methods of the printed parts

What is more, we offer services of dry electro polishing (Dlyte) on the parts supplied by the Customer.

All parts created and processed in our lab can additionally be heat treated in the inert gas environment.

Any other testing needs?

Contact us!

605 602 543