Two EDC material engineers – Tomasz Didenko (PhD) and Marcin Zak have recently published a very interesting article on turbine shroud cracking phenomenon – “Turbine Shroud Cracking Investigation and Repair“. The material has been accepted by the prestigious “Journal of Failure Analysis and Prevention”.

Two EDC material engineers – Tomasz Didenko (PhD) and Marcin Zak have recently published a very interesting article on turbine shroud cracking phenomenon – “Turbine Shroud Cracking Investigation and Repair“. The material has been accepted by the prestigious “Journal of Failure Analysis and Prevention”.

Below you will find an abstract from this publication:

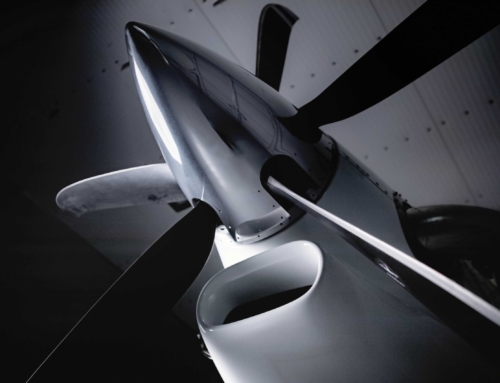

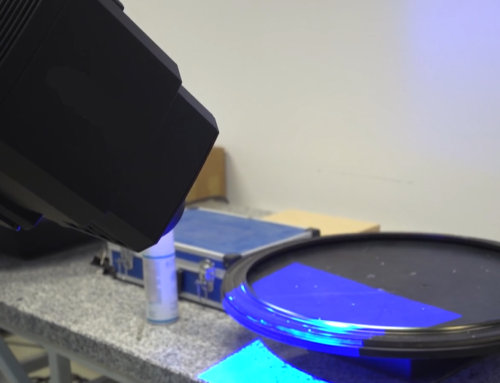

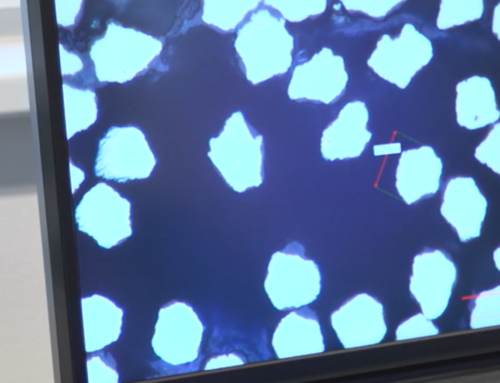

“Outer shroud segments fabricated from a cast 310 stainless steel were found to have cracked following extended service. Several of these cracked shrouds were sent to the GE-Poland Materials Laboratory for metallurgical investigation with a view to determine the cause of cracking. Detailed investigation revealed cracking to be associated with a sigma phase, a brittle TCP intermetallic, which had developed over time during engine operation. Initial attempts to weld repair the cracks proved unsuccessful as cracks were discovered both during and after the weld repair procedure. A new weld repair procedure incorporating a pre-weld solution annealing heat treatment to remove the sigma phase before welding was successfully developed, thus alleviating the cracking concern.”

The article has just been published and is avaliable here.