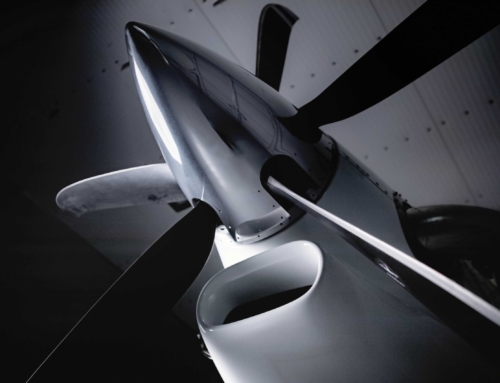

The first clean-sheet turboprop engine in 50 years – GE’s Catalyst, designed in the great part by EDC engineers, is nearing its first flight. How the works are going? What is exceptional in that engine? Will it open up more markets in terms of passenger connectivity thanks to its increased range?

To get the answers to those questions and learn more about GE’s Catalyst itself, we encourage you to read the interview on Aviation Source website with EDC own – Janek Biskupski (Catalyst Systems Engineering Leader) and with David Kimball from GEAC, Prague, Czech Republic, who is Catalyst Product Line Leader.

The text will give you a quick overview of the Catalyst Program. Its recent advancements are a big source of pride not only for the Catalyst Team, but also for the entire EDC. GE’s Catalyst is the first engine completely designed outside of the US by GE. Quite a number of people from across Europe (i.e. Poland, Italy, Czech Republic, Turkey and Germany) worked on that product, but about 50% of the engineers engaged in the program were from EDC.

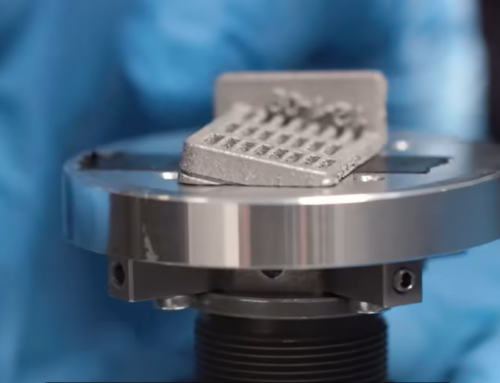

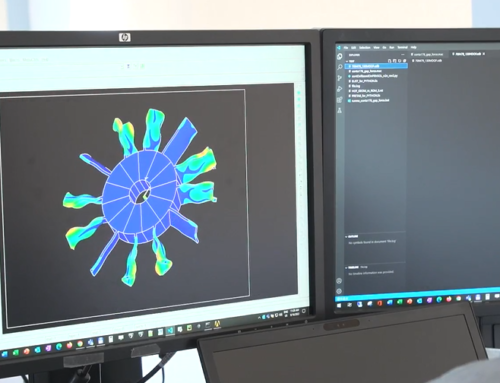

Our engineers were responsible for the design of high and low pressure turbines, the compressor, bearings, sumps and engine systems, like secondary air or lube system. The project also meant advancing the latest technologies, for example aspects of the high pressure turbine cooling used in the engine or additive structures design (4 out of 5 large additive structural components to be certified were designed in Warsaw) making EDC a leading design center of additive load-bearing structures.

If you would like to know more – just click this link to read the whole article on the Aviation Source website.